Boost Your Bottom Line: The Secret Sauce of Successful Gas Meter Sizing!

Selecting the right size gas meter for your facility is a critical step in optimizing operating costs and ensuring a steady gas supply. The key lies in understanding your facility's natural gas or propane consumption, typically expressed in British Thermal Units per hour (Btu/hr), versus the supply. Let's delve into the essential factors and formulae that guide this process.

1. Calculate Demand

The simplest method for calculating demand is adding up the ratings of all gas appliances in Btu/hr’s. Every appliance has a plate with this rating. If the rating is in anything other than Btu/hr’s, then it will need to be converted before adding. Below are examples of ratings.

Dryer 30,000 Btu/hr

Furnace 80,000 Btu/hr

Kitchen Range 50,000 Btu/hr

Water Heater 40,000 Btu/hr

TOTAL DEMAND: 200,000 Btu/hr

A gas meter rated at a maximum continuous capacity of 250 cfh (American AC250) is capable of providing 250,000 Btu/h of natural gas at a 0.5 iwc (inches water column) differential. If the meter’s capacity is greater than the demand, your gas meter’s size is acceptable. So, a home with a total demand of 200,000 Btu/h as given in the above example will be fine using this size gas meter.

2. Diversity Factor

It is rare for all the appliances to be used at the same time, so when sizing, companies will apply a diversity factor. This factor is determined by evaluating if all appliances will be used at the same time. However, when sizing, it’s important to account for the fact that at some point in the meter’s life, all appliances could be used simultaneously. Our organization frequently uses a diversity factor of 85% which would bring the house’s demand in the example above to 170,000 Btu/hr.

3. Consider the desired meter differential

The meter differential is the pressure required to pass the desired flow through the meter. Typically meters are sized off of the 0.5 iwc differential, however they can operate at higher differentials. Operating at a higher differential increases meter wear, but decreases initial capital costs. If you would like to size the meter off a differential other than the badged rate, the manufacturer will have sizing specifications available to you.

4. Factor in Line Pressure

Typically, residential gas is delivered at approximately 0.25 psi or 7 inches of water column. Some residential and commercial facilities may operate at higher line pressures. Determine the line pressure your facility uses, considering either Pounds per Square Inch (PSI) or Inches of Water Column (iwc). Elevated line pressure will drive more energy through your meter allowing a smaller meter to supply a larger facility. The meter manufacturer can provide sizing documentation to show the meter's capacity at different line pressures.

5. Tailor Sizing to Your Needs

Now, the formula to determine the appropriate meter size involves considering the specific gas type, capacity, and line pressure.

For natural gas, use the formula:

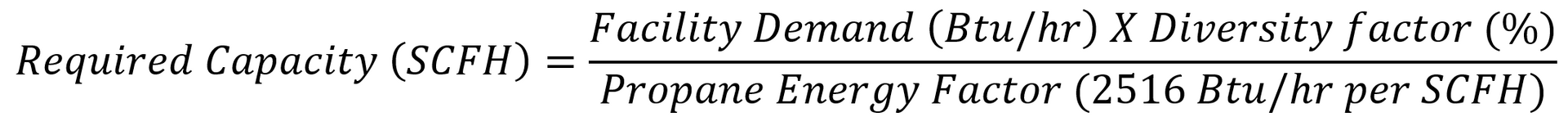

For propane, adapt the formula:

Once you have the required capacity, you can use the manufacturer’s sizing chart for both the meters desired operating differential and your facility’s line pressure to determine the correct sizing. You can find an example of a

meter sizing chart

provided by Dresser/ Roots Utility.

6. Seek Professional Advice and Verify

While these formulas provide a foundation, it's advisable to consult with gas metering professionals at Energy Economics, Inc. to ensure accuracy. They can help refine your calculations based on specific facility needs and industry standards, ensuring the chosen meter aligns perfectly with your system's requirements.

Please reach out to our knowledgeable team with any further questions.

Thank you!

Experienced Experts. Superior Support.

Energy Economics, Inc.

109 South Street SE

Dodge Center, MN 55927

Toll-Free: (800) 733-2557

Outside US: (507) 374-2557

Fax: (507) 374-2646