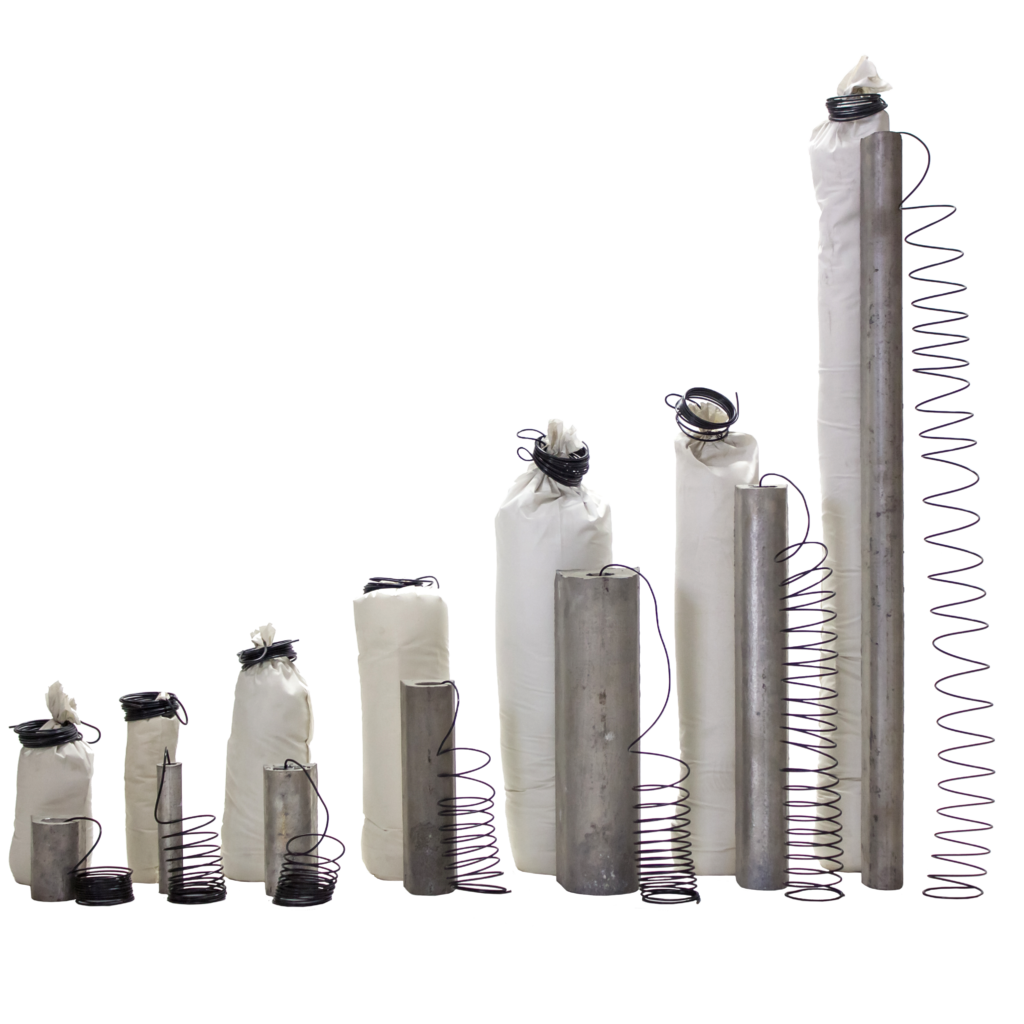

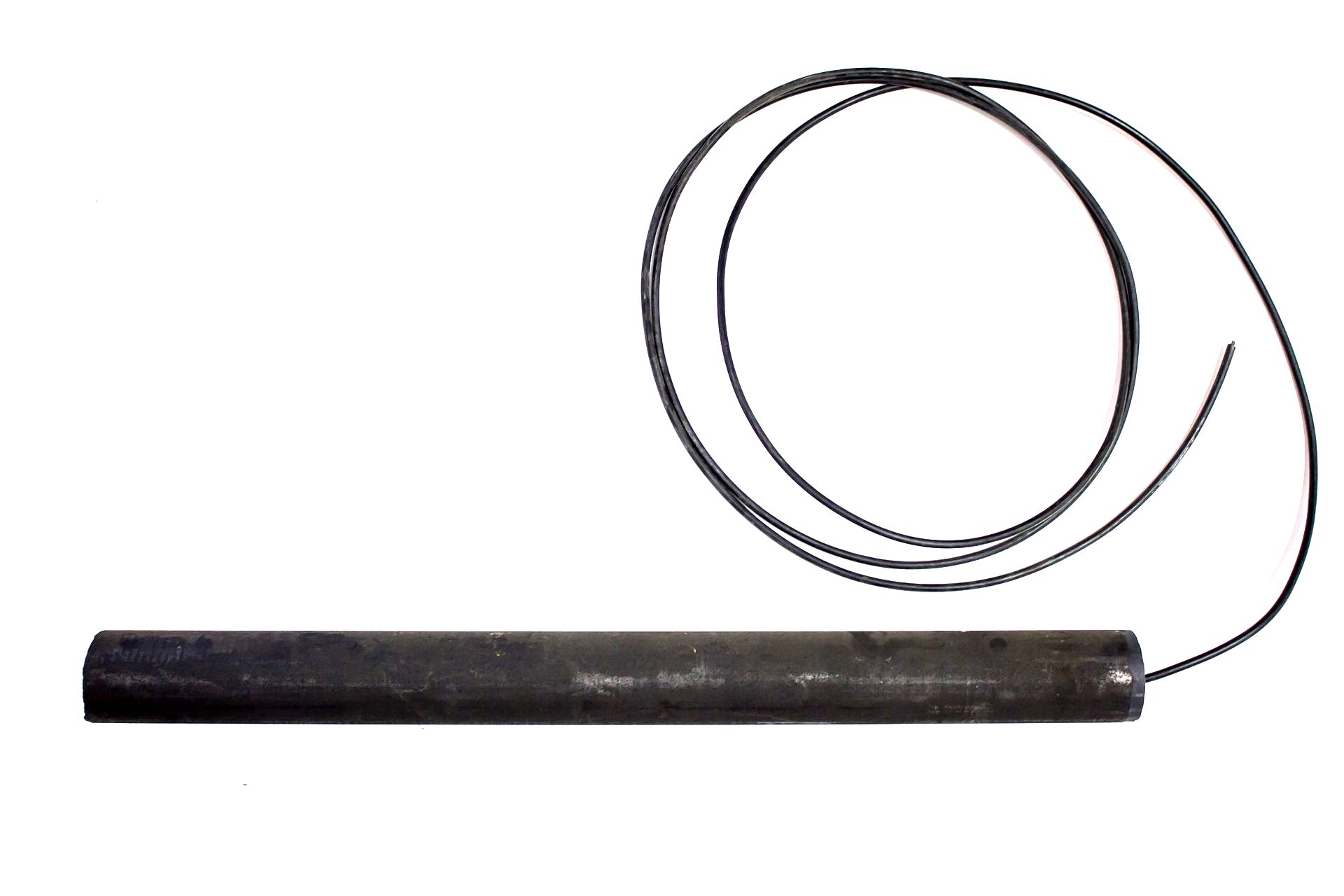

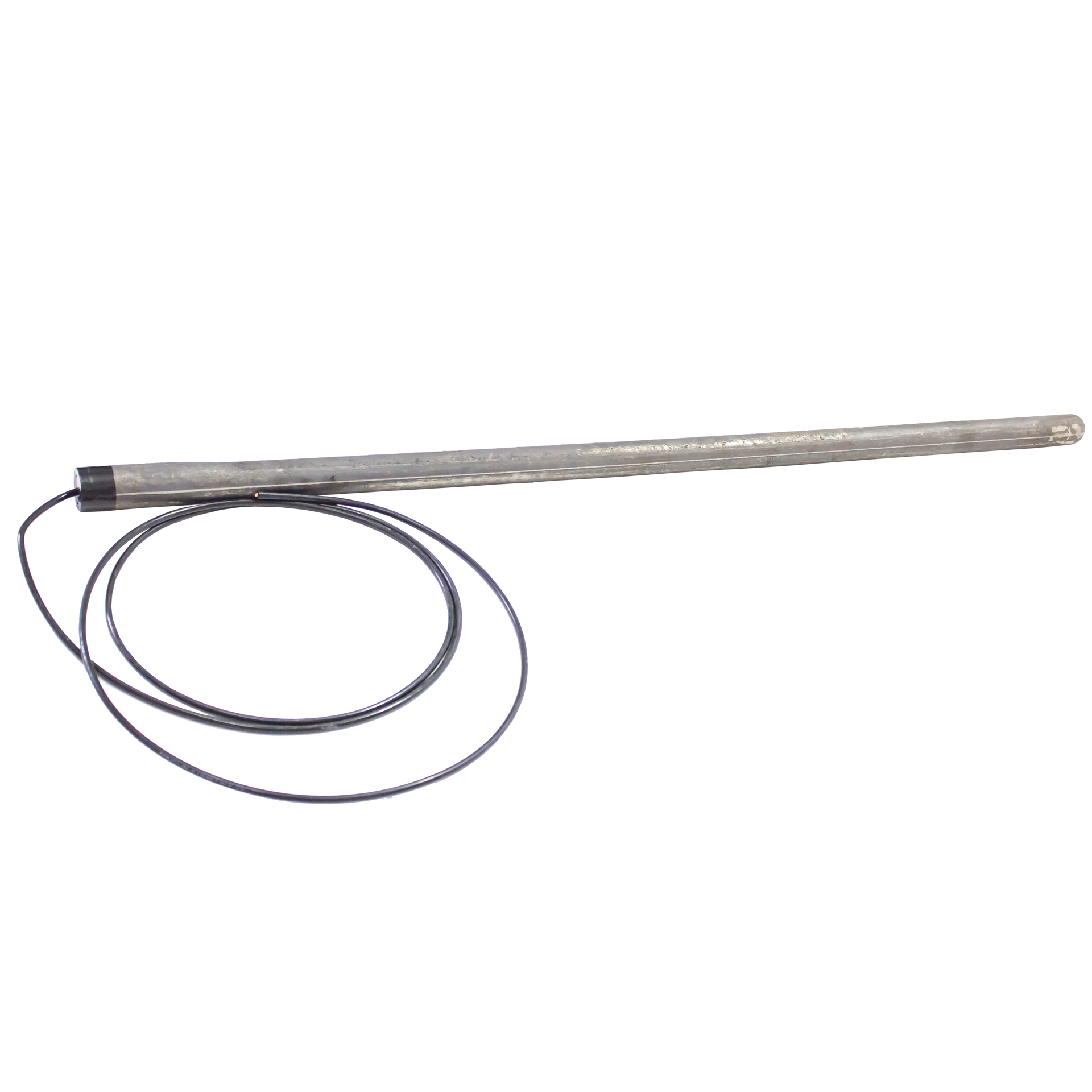

Anodes & Cathodic Protection

Please reach out to our knowledgeable team with any further questions.

Thank you!

Trust - Experience - Quality

Energy Economics, Inc.

109 South Street SE

Dodge Center, MN 55927

Toll-Free: 800-733-2557

Outside US: 800-733-2557

Fax: 800-733-2557